The concept of bulk modulus is fundamental in the study of material science and mechanical engineering. It plays a crucial role in understanding how materials respond to pressure and external forces. The bulk modulus, often denoted as K, is a measure of a material’s resistance to uniform compression. By analyzing the dimensions of bulk modulus, scientists and engineers can predict how substances will behave under different conditions, which is vital for applications ranging from construction to aerospace engineering. Understanding the dimensional formula of bulk modulus helps in ensuring accurate calculations, scaling, and modeling of real-world systems, providing insight into the intrinsic mechanical properties of materials.

Understanding Bulk Modulus

Bulk modulus is defined as the ratio of the infinitesimal pressure increase to the resulting relative decrease of the volume. Essentially, it measures how incompressible a material is. When a material is subjected to uniform pressure from all directions, its volume changes slightly. The bulk modulus quantifies this change, allowing engineers to compare the rigidity of different materials. For example, a material with a high bulk modulus, like steel, resists compression more than a material with a low bulk modulus, such as rubber.

Formula of Bulk Modulus

The bulk modulus (K) is mathematically expressed as

- K = -V (dP/dV)

Where

- K = bulk modulus

- V = original volume of the material

- dP = infinitesimal change in pressure

- dV = infinitesimal change in volume

The negative sign indicates that an increase in pressure leads to a decrease in volume. This formula is key for deriving the dimensions of bulk modulus, which is important in dimensional analysis.

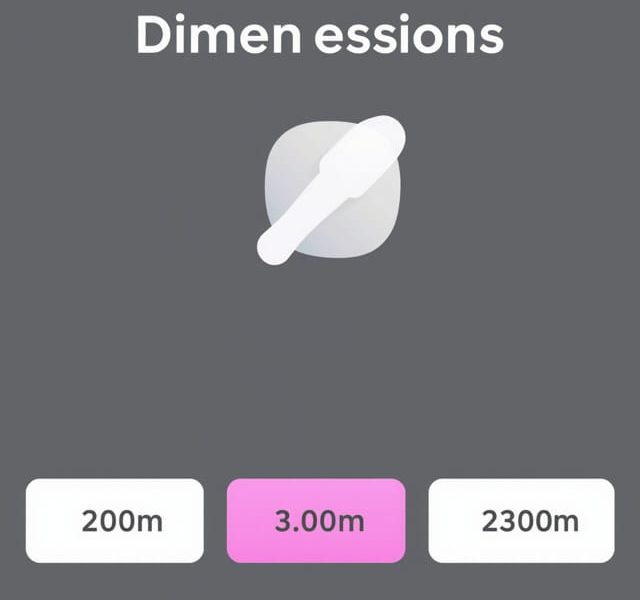

Dimensions of Bulk Modulus

To derive the dimensions of bulk modulus, we start from its fundamental definition. Pressure is force per unit area, and bulk modulus has the same dimensional units as pressure. Thus, understanding the dimensions of force and area is essential.

Step 1 Dimensions of Force

Force is defined as mass times acceleration. In symbols

- F = m à a

Where m is mass and a is acceleration. Acceleration is the rate of change of velocity per unit time, and velocity itself is distance per unit time. Therefore

- [a] = [L][T]^-2

- [F] = [M][L][T]^-2

Here, [M], [L], and [T] represent the dimensions of mass, length, and time respectively.

Step 2 Dimensions of Area

Area is defined as the product of two lengths. Therefore

- [A] = [L]^2

Step 3 Dimensions of Pressure

Pressure (P) is force per unit area, so its dimensional formula is

- [P] = [F] / [A] = ([M][L][T]^-2) / [L]^2 = [M][L]^-1[T]^-2

Since bulk modulus has the same units as pressure, its dimensions are identical.

Dimensional Formula of Bulk Modulus

Based on the analysis of force and area, the dimensional formula of bulk modulus is

- [K] = [M][L]^-1[T]^-2

This indicates that bulk modulus depends directly on mass, inversely on length, and inversely on the square of time. Recognizing these dimensions allows scientists to apply dimensional analysis techniques to check equations involving bulk modulus for consistency.

Applications of Dimensional Analysis

Dimensional analysis is a powerful tool in engineering and physics. By knowing the dimensions of bulk modulus, engineers can

- Verify the correctness of derived equations involving pressure, volume, and elasticity.

- Scale experiments or prototypes to real-world systems while maintaining similar mechanical behavior.

- Predict material behavior in conditions where direct experimentation is difficult or impossible.

Relation to Other Mechanical Properties

The bulk modulus is closely related to other material properties like Young’s modulus and shear modulus. Young’s modulus measures a material’s response to uniaxial stress, while shear modulus describes deformation under shear stress. Understanding these relationships requires consistent dimensional formulas

- Bulk modulus [M][L]^-1[T]^-2

- Young’s modulus [M][L]^-1[T]^-2

- Shear modulus [M][L]^-1[T]^-2

All three share the same dimensional formula, highlighting that they are forms of stress measurements expressed per unit area. This consistency reinforces the universality of dimensional analysis in material science.

Practical Implications of Bulk Modulus Dimensions

Knowing the dimensional formula of bulk modulus is not just theoretical; it has practical implications. For instance, in designing hydraulic systems, engineers need to select fluids and materials that resist compression. Materials with a higher bulk modulus are preferable in situations requiring minimal volume change under high pressure. Similarly, in acoustics, bulk modulus affects the speed of sound in a medium, which is critical in designing musical instruments, sonar systems, and speakers.

Summary

The dimensions of bulk modulus, [M][L]^-1[T]^-2, provide essential insight into the mechanical behavior of materials under compression. By understanding these dimensions, scientists and engineers can ensure accurate calculations, perform dimensional checks, and scale models effectively. Bulk modulus serves as a cornerstone in mechanics, connecting theoretical principles with practical applications, from construction and aerospace to acoustics and fluid dynamics. Its dimensional analysis confirms its equivalence to pressure, linking mass, length, and time in predictable ways that guide material selection and design decisions across various engineering disciplines.